Finished Vehicle Solutions:

Real-Time Quality Control for High-Volume Ports

Automate Pre-Delivery Inspection (PDI) checks, cut processing time by up to 90 percent, and deliver showroom-ready cars the moment they hit the dock.

The End-to-End UVeye Inspection Journey

Strategic Touchpoints for Consistency and Quality Control:

The End-to-End UVeye Inspection Journey

Strategic Touchpoints for Consistency and Quality Control:

360° Visibility

Exterior, roof, underbody & tires scanned in one pass, providing a single source of truth

AI-Powered Efficiency

Automation slashes manual touch-time and keeps vehicles moving

Evidence-Backed Accountability

Time-stamped images stop damage and warranty disputes before they start

Damage Attribution

Know exactly when and where defects occur across truck, rail, or ship legs

Liability Reduction

Clear documentation ends finger-pointing between OEMs, carriers, and port operators

Consistent Quality Assurance

Maintain standards across every transit stage

Final Quality Check

Catch transit-induced defects before release, protecting brand reputation

Customer Satisfaction

Deliver clean, damage-free vehicles that build trust

Recurring Defect Detection

Surface chronic issues, trace root causes, and prevent repeats

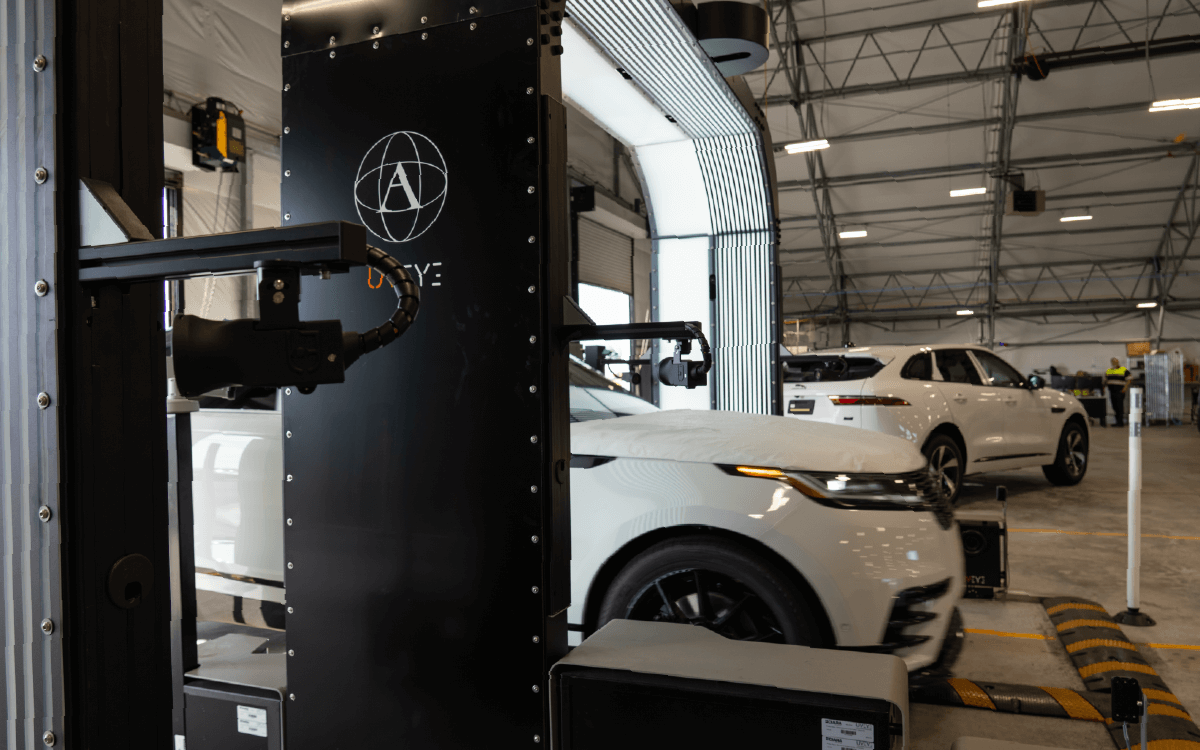

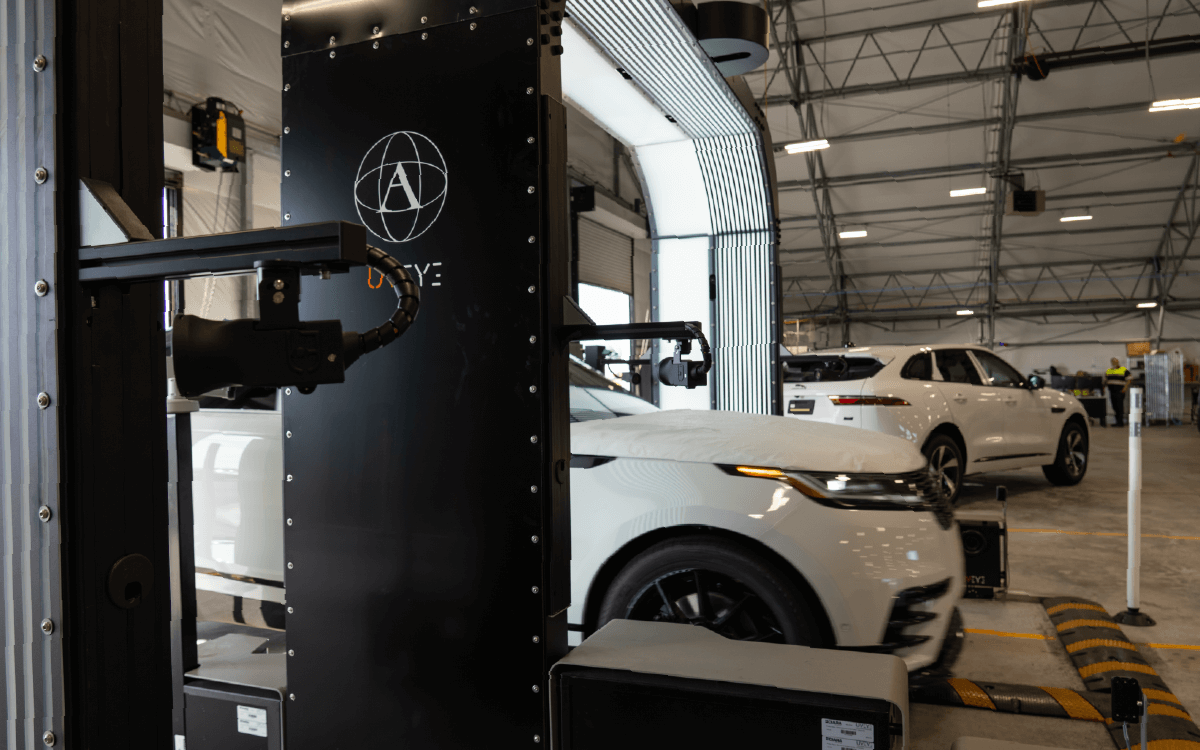

How UVeye Works

Roll-Off

Vehicles leave the vessel or railcar and drive straight through the UVeye portal.

Instant Analysis

AI flags exterior scuffs, underbody leaks, rim damage, and tire objects in seconds.

Action & Handoff

Port teams receive a digital report; on-site repairs are scheduled or the vehicle is cleared for outbound transport.

Ready to take the next step?

Join the movement of data-driven inspections.

Elevate your operations and refine your strategy with UVeye.