JLR plans to use Apollo for interior inspections, including engine noise detection. Ongoing optimization and performance tracking will be supported through Monthly/Quarterly business reviews with UVeye and port vendors.

Overview

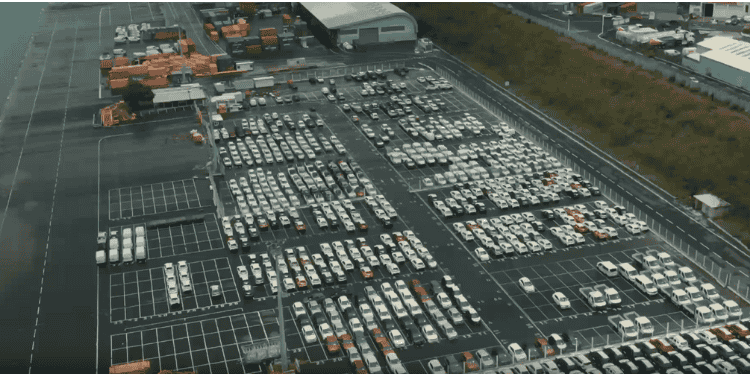

Jaguar Land Rover has partnered with UVeye to transform its Customer Acceptance Line (CAL) process across three critical U.S. seaports: Brunswick, GA, Baltimore, MD, and Hueneme, CA. This initiative integrates UVeye’s automated inspection technology into JLR’s inbound vehicle quality control process, ensuring that vehicles arriving from overseas are free of defects before reaching JLR end customers.

The Objectives

- Improve defect detection to catch even the smallest imperfections affecting JLR customer satisfaction.

- Boost CAL efficiency and capacity with automated scanning, reducing manual inspection time and allowing more vehicles to be processed.

- Ensure clear traceability by documenting each vehicle’s condition to reduce liability disputes and assign responsibility for damage.

- Enhance standardization and cost control by centralizing CAL at three ports, ensuring consistent inspections, enabling immediate repairs, and cutting dealership inspection costs.

Impact of UVeye

Key Results

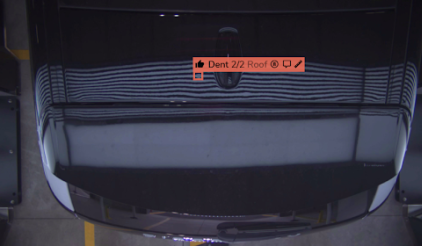

- More than 10% of vehicles had defects detected before delivery to dealerships during the pilot. These defects were detected by UVeye system and missed by visual inspectors.

- JLR’s ability to map and compare defects to pre-shipping manufacturing data using the reports from UVeye allows them to pinpoint whether issues occurred at the factory, during transport, or at the port

Inspection Technology & Capabilities

UVeye systems, two lanes pers tire (total of 6 systems), scan every arriving vehicle, capturing high-resolution imagery and advanced light reflection data to detect body, underbody, and tire damage. Subtle issues, such as shallow dents, faint color variations, or minor scuffs, often missed by manual inspection, are reliably identified.

Operational Enhancements

- Automated VIN Matching links scans to each vehicle for accurate traceability.

- Direct Data Uploads: Defect documentation flows in real-time into UVeye’s UVcamp portal, allowing seamless defect analysis and reporting.

- Tablet-based documentation improves efficiency and record-keeping.

- Integration with Apollo allows advanced inspections, including engine noise detection.

Benefits to JLR

- Fewer disputes: Clear, timestamped reports reduce dealership disputes.

- Automated detection increases inspection accuracy and consistency.

- Chronic defect tracking identifies recurring issues and their source.

- Cost savings: Early damage detection lowers repair costs, rework, and customer dissatisfaction.

Key Learnings & Next Steps