Setting the Standard for OEM Quality & Efficiency

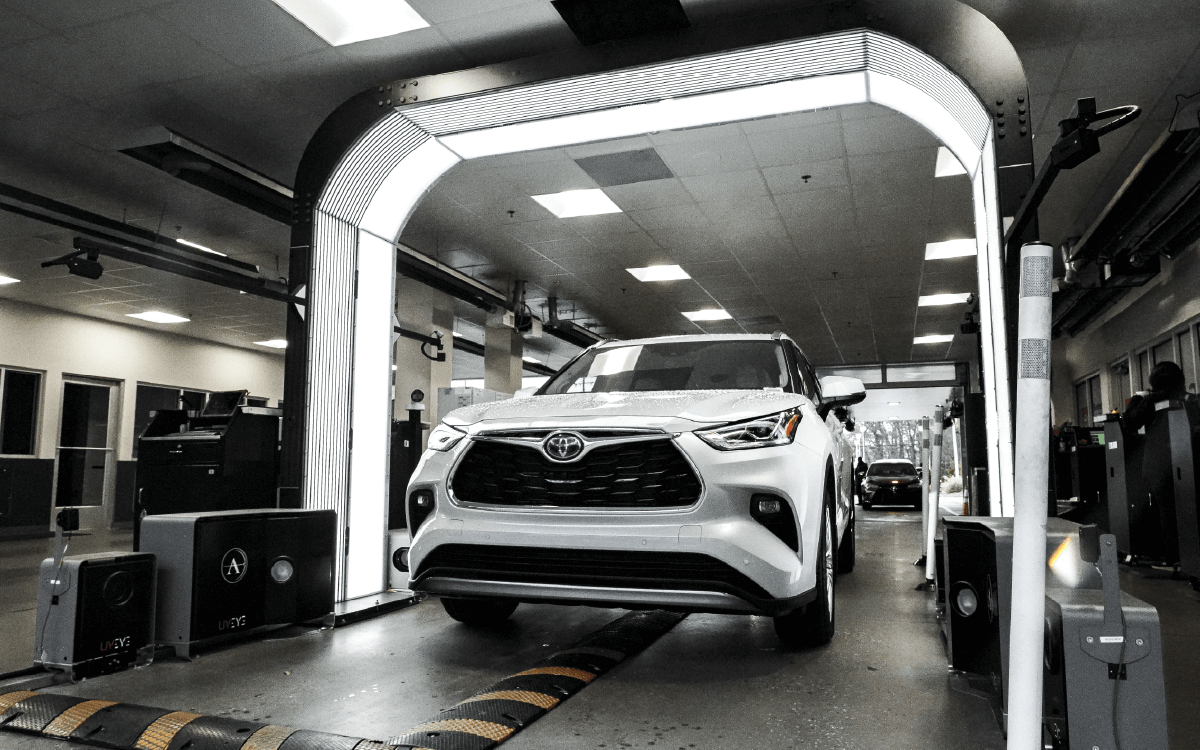

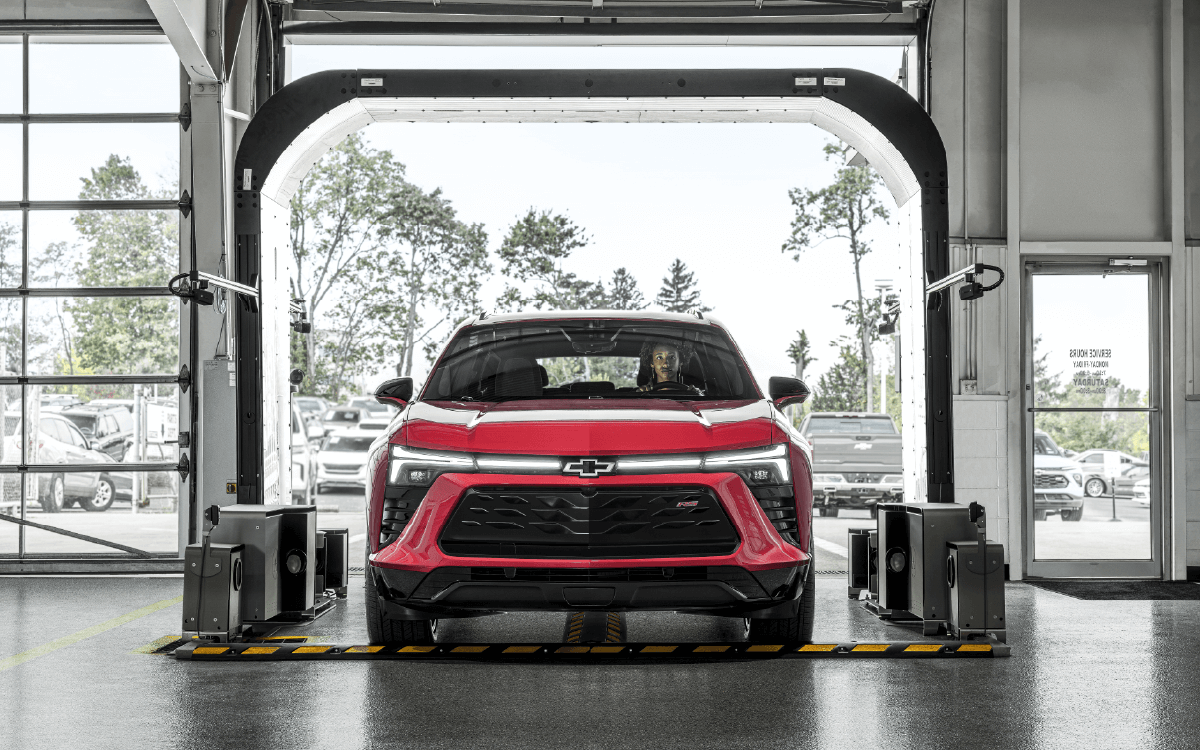

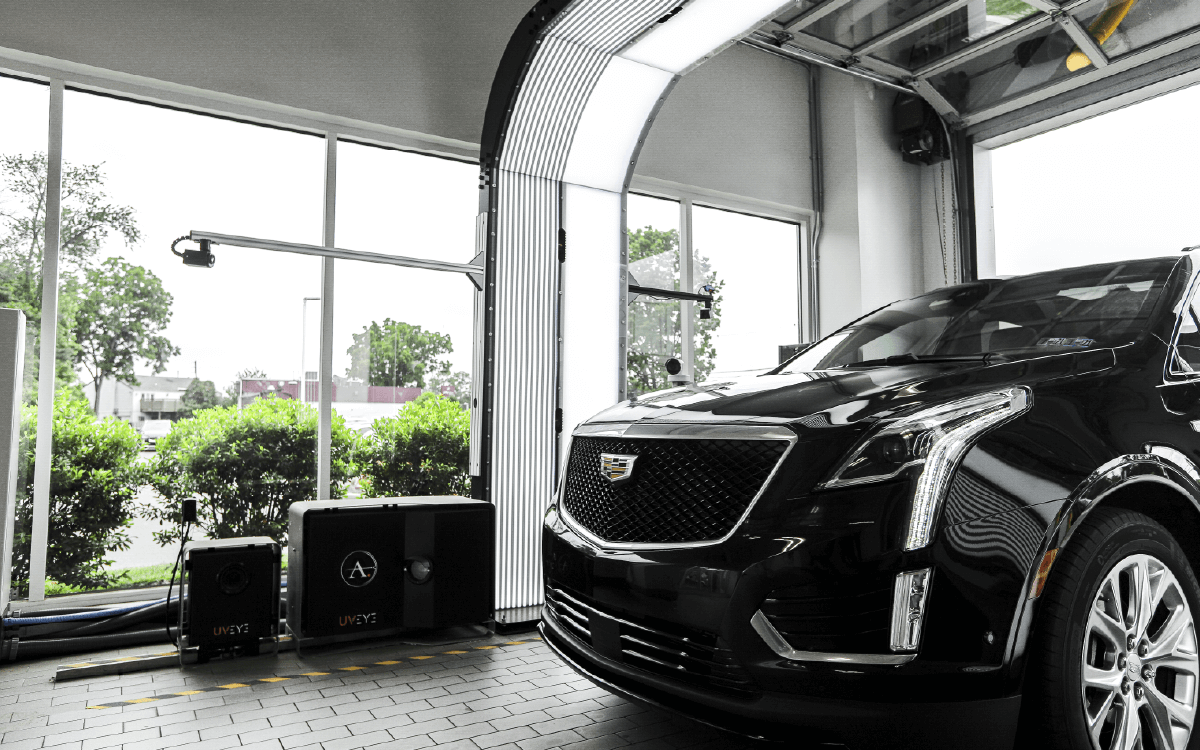

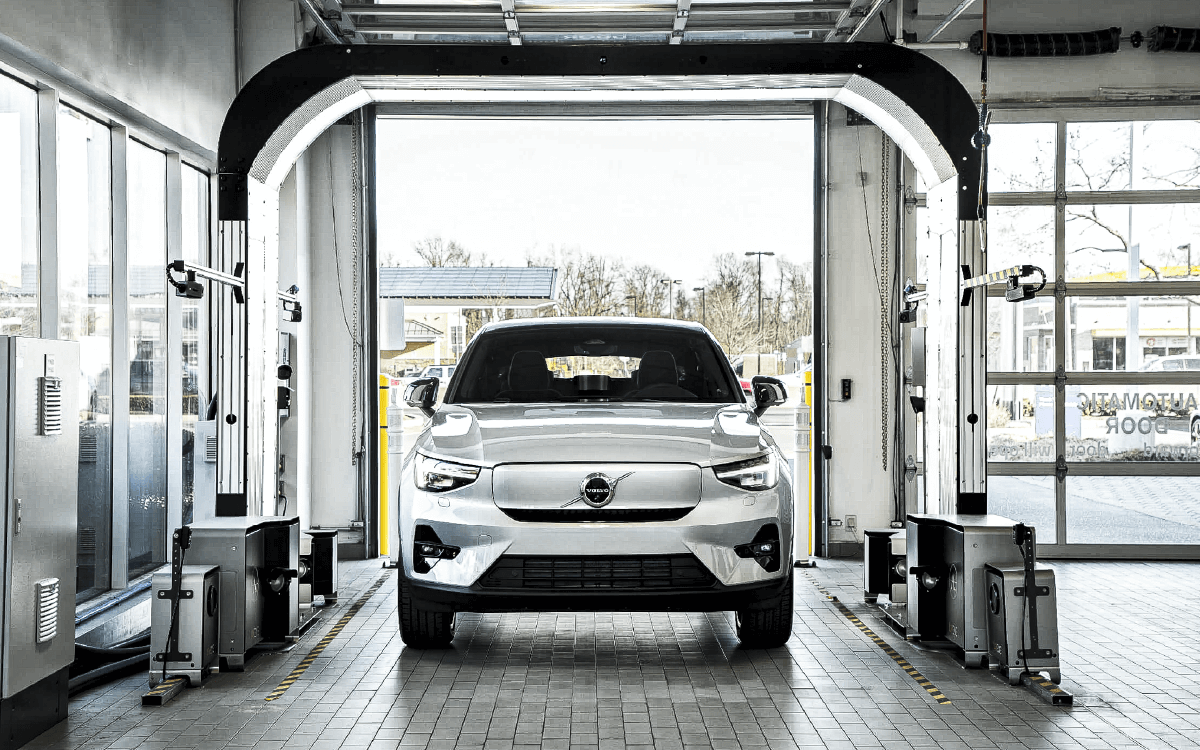

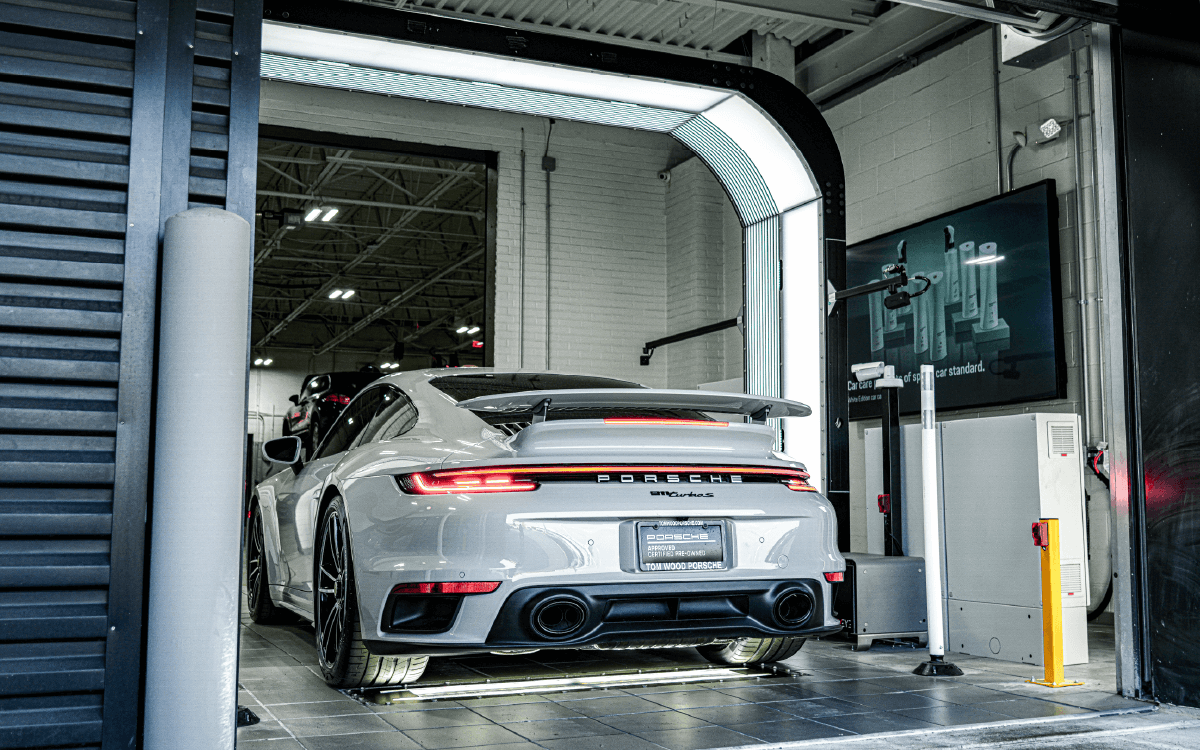

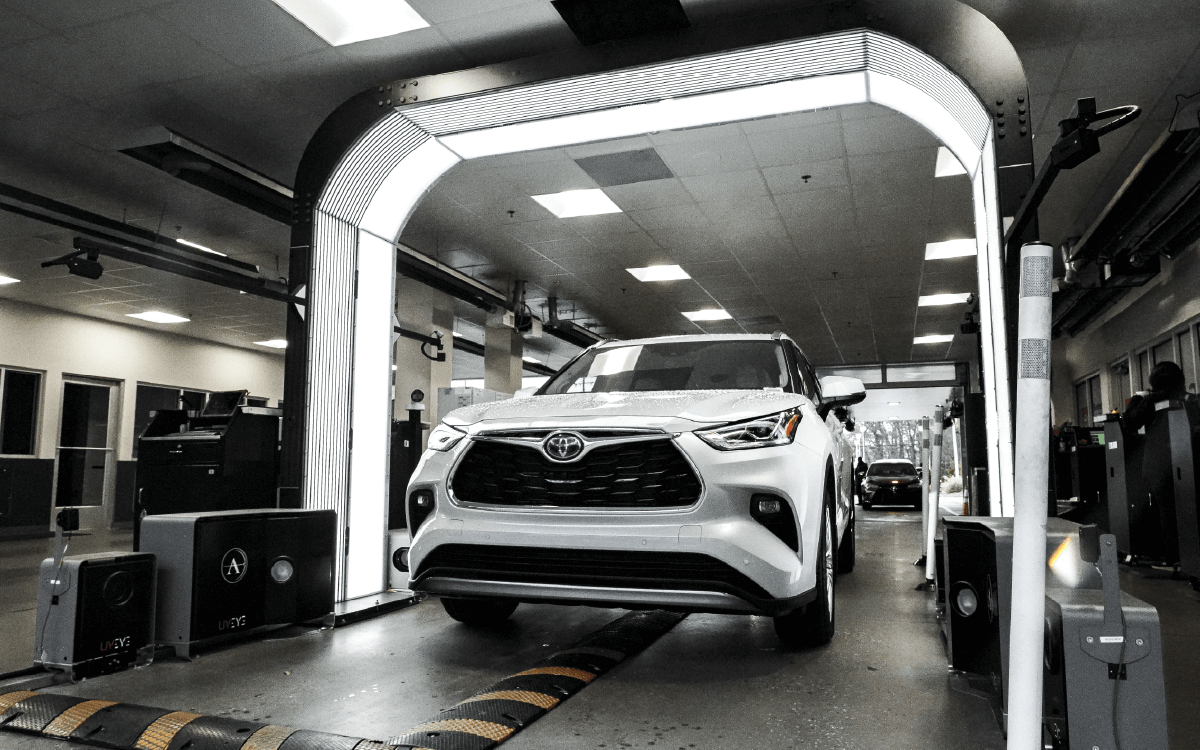

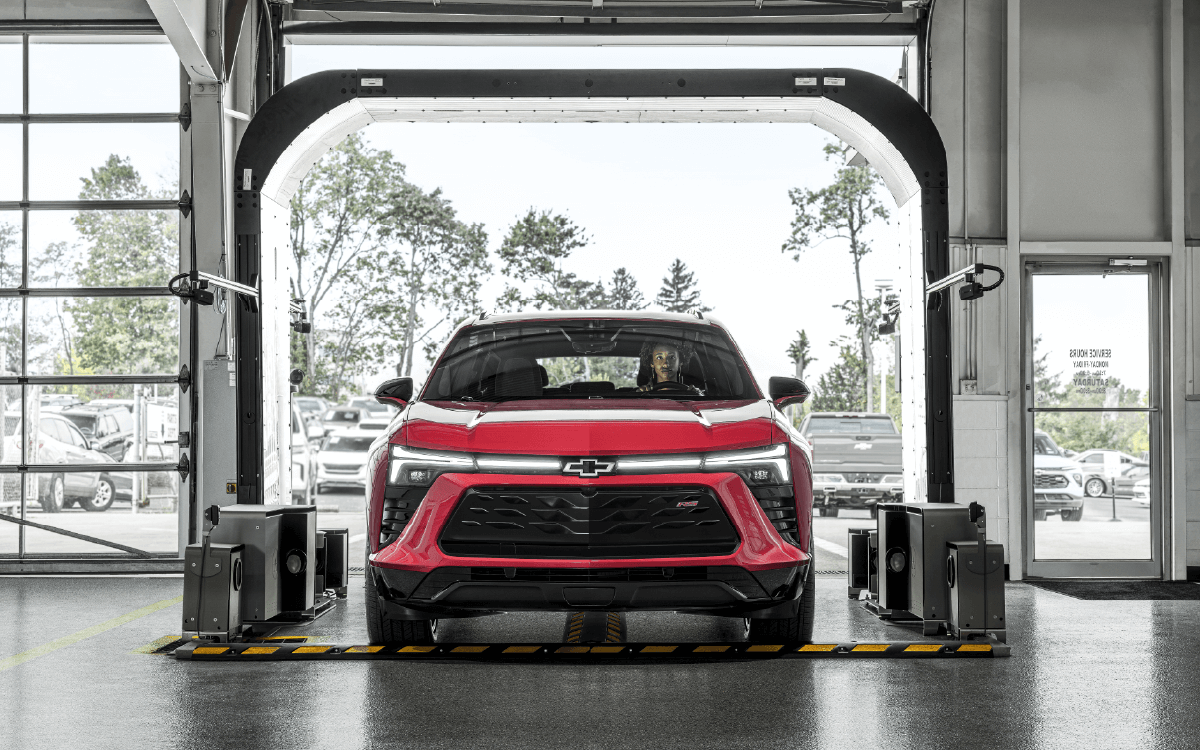

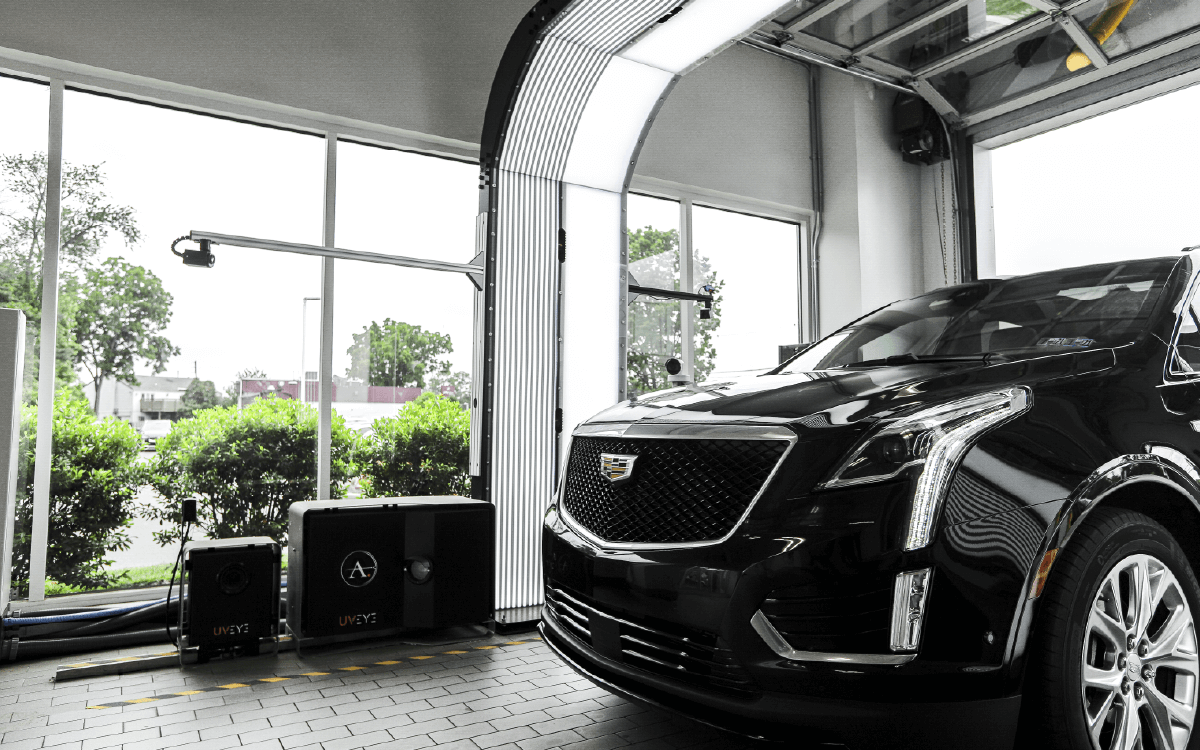

Ensure every vehicle meets the highest quality standards—from the assembly line to seaports to the dealership. UVeye delivers precision inspections at every critical point in the vehicle assembly and logistics value stream.

The End-to-End UVeye Inspection Journey

Strategic Touchpoints for Consistency and Quality Control:

The End-to-End UVeye Inspection Journey

Strategic Touchpoints for Consistency and Quality Control:

Assembly Line Inspections

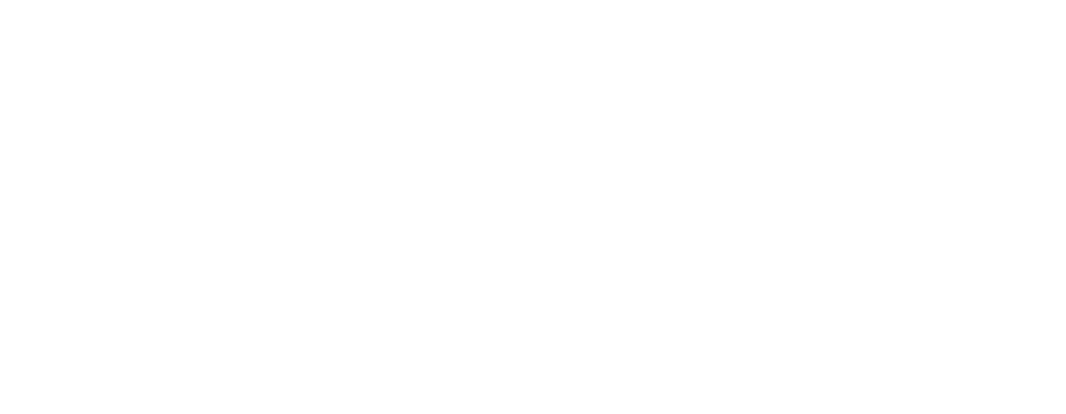

- Early Defect Detection: Identify manufacturing defects before vehicles leave the plant allowing OEMs to fix issues and improve up-stream processes Common detections are for surface damage (dents, scratches), foreign objects in tires (i.e., nails and screws) and missing fasteners from.

- Comprehensive Inspection: Rather than relying on a low-volume quality audit at the end of the assembly line, OEMs can capture and record the condition of every vehicle produced.

- Improve Quality: Ensure wheels, tires, and emblems match the build sheet and are assembled correctly. Detect any incorrect or missing fasteners on the vehicle underbody, lights and accessories.

- Track Paint Quality: UVeye can also measure paint quality and consistency across panels.

- Root Cause Analysis: Detect patterns in vehicle condition to prevent recurring quality issues and enable a virtual andon cord for assembly engineering.

- Efficiency Gains: Redeploy resources from inspection processes to repair and remediation workstations.

- Vehicle Birthmark: Capture and establish vehicle condition the moment its roadworthy as a reference for all future comparisons.

Transportation Monitoring (Trucks, Ships, Trains)

- Damage Attribution: Time-stamped scans pinpoint where and when damage occurred, allowing OEMs to hold transportation partners and processes accountable. .

- Liability Reduction: Documentation and transparency eliminates disputes between OEMs and logistics providers and allows all parties to fix recurring issues.

- Consistent Quality Assurance: Maintain standards through every transit stage.

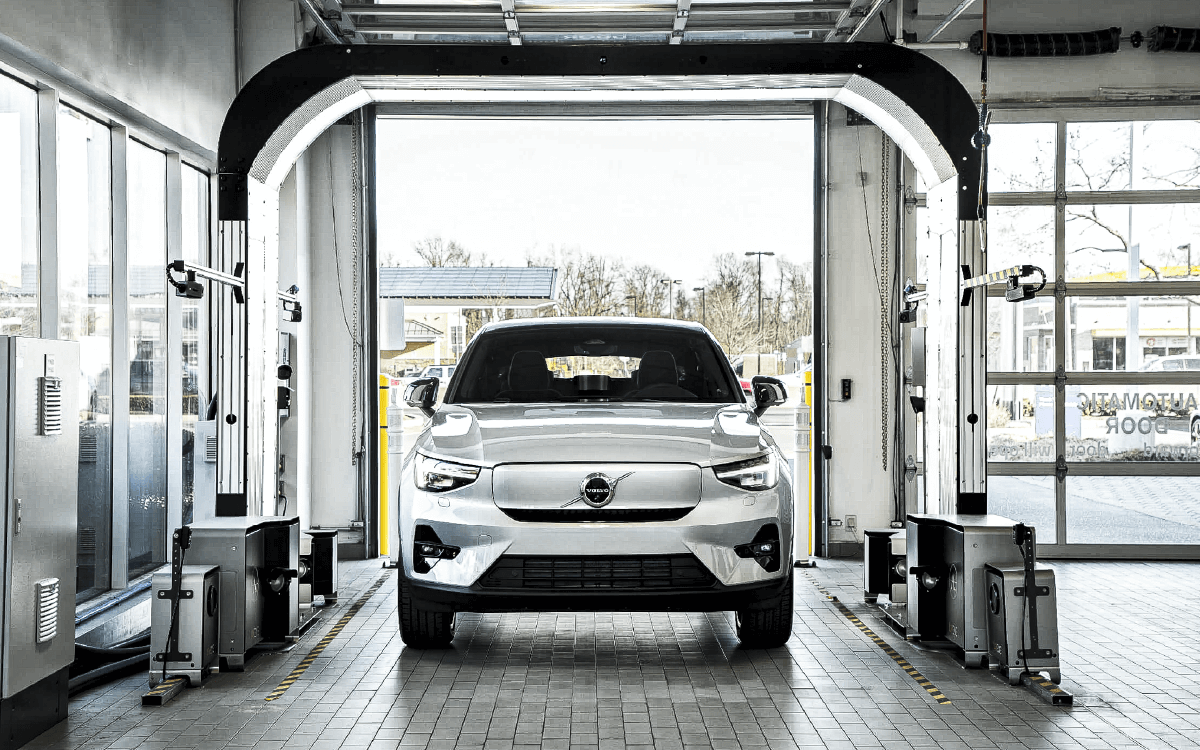

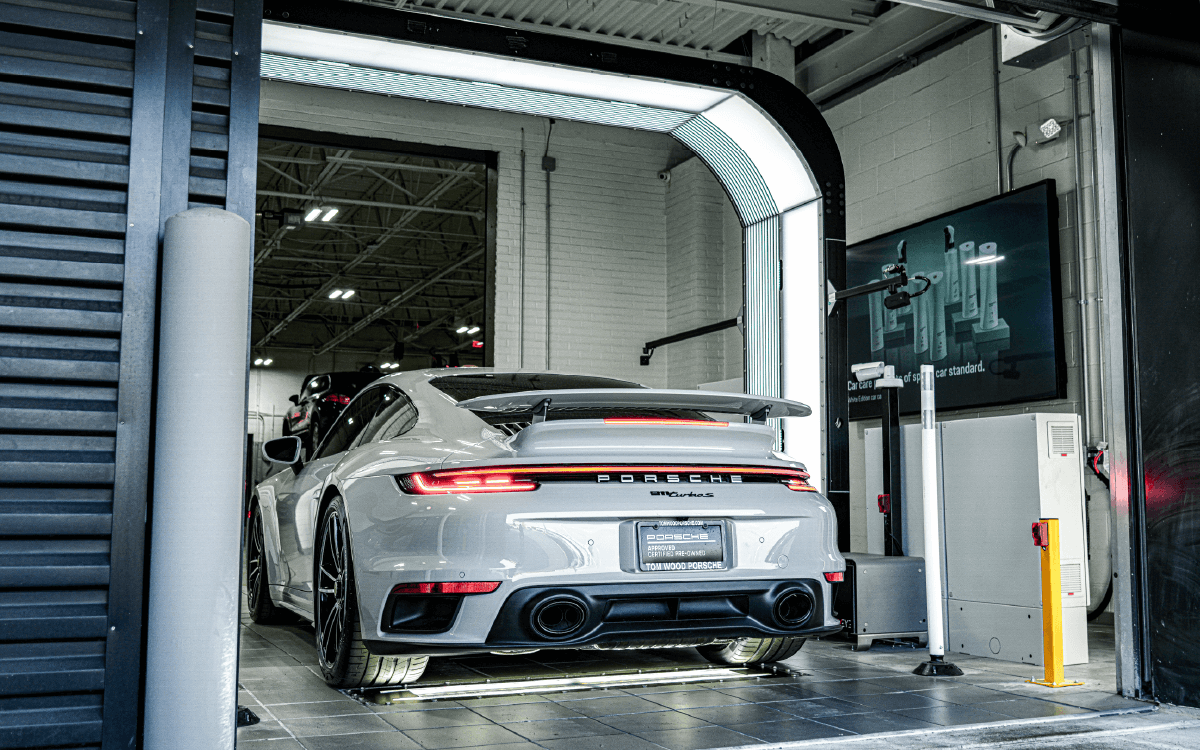

Pre-Delivery Inspection (PDI)

- Final Quality Check: Identify transit-induced damage before customer delivery.

- Customer Satisfaction: Deliver flawless vehicles, enhancing brand trust.

- Cost Savings: Reduce downstream repairs and warranty claims through early detection.

- Root Cause Analysis: Detect patterns in vehicle condition to prevent recurring quality issues and enable the highest quality standards

Driving Excellence with UVeye

Network-Wide Standardization

Consistent, brand-aligned inspections across assembly plants, logistics hubs, and dealer networks.

Operational Efficiency

Drive-through inspections in seconds, reducing PDI and service cycle times by up to 90%.

Comprehensive Detections

Catch all damage and quality issues for remediation at the source, and before it arrives to the customer

Data-Driven Insights

AI-powered reports uncover trends for proactive quality improvements and allows you to track vehicle condition before it arrives to the customer, but also after use with our installation base of dealerships, allowing engineering teams to track vehicle quality as they are used and age.

Scalability

Modular systems deploy seamlessly across plants, ports, and dealer networks.

Risk Reduction

Time-stamped inspections minimize policy spend, damage disputes, and liability at every stage of the value chain.

Seamless Integration

Works with any OEM platforms and PLC for minimal up-front technology investment by OEMs.

Future-Proofing

Scalable to support digital retailing, automated trade-in appraisals, and evolving OEM programs.

Pay-for-what-you-use

UVeye platform requires no upfront capital expenditure for OEMs, paying for only what is being scanned and does not require any costly upgrades for new models, trims levels, or paint colors.

Ready to take the next step?

Join the movement of data-driven inspections.

Elevate your operations and refine your strategy with UVeye.